Wood processing

Keeping the sawmill's song going: Rationalising wood processing with automatic lubrication

The wood processing industry relies on efficient machinery to transform raw wood into valuable products. However, the maintenance of this equipment poses a major challenge for lubrication.

Firstly, dust, dirt and wood debris create a harsh environment that accelerates wear on key components. Secondly, ensuring consistent manual lubrication across complex production lines can be time-consuming and labour-intensive.

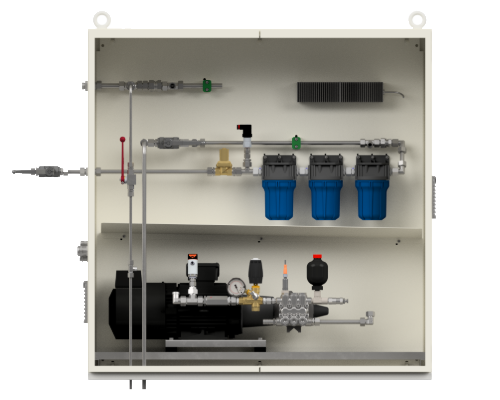

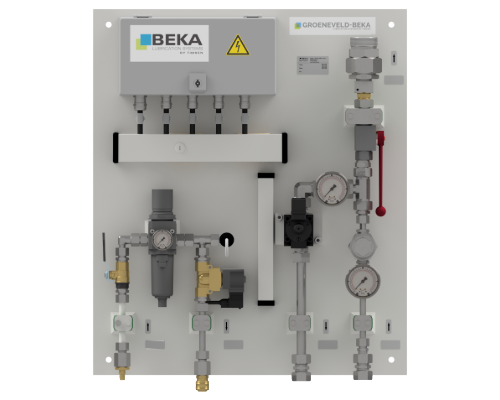

Automatic lubrication systems from Groeneveld-BEKA offer a harmonised solution for the woodworking industry

Automatic lubrication delivers precise quantities of lubricant at pre-programmed intervals, minimising wear and preventing system failures that can interrupt the production flow.

The automation of routine lubrication tasks frees up valuable working time. Your team can concentrate on optimising production processes and quality control measures.

Consistent lubrication promotes optimum performance and extends the life of your valuable machinery, reducing replacement costs.

Automatic systems eliminate the need for personnel to enter hazardous areas around moving parts for lubrication, minimising the risk of slips, falls and injuries.

Precise application minimises lubricant splashes and overspray, keeping your production area clean and reducing the risk of slipping.

Minimise lubricant waste and potential environmental pollution in your wood processing plant.

Find the right product for you!

Groeneveld-BEKA's automatic lubrication systems offer a high-performance solution for the woodworking industry