Port Equipment

Rationalisation of container handling through automatic lubrication

The relentless pace of modern harbours demands top performance from container handling equipment. However, maintaining these vital machines poses a particular challenge.

Firstly, harsh environments where they are constantly exposed to salty air, dust and dirt accelerate the wear and tear of critical components. Secondly, the increasing presence of electric vehicles in the industry is leading to new considerations regarding lubrication procedures. Traditional manual methods are often not suitable for these advanced machines, and safety is paramount for all types of equipment.

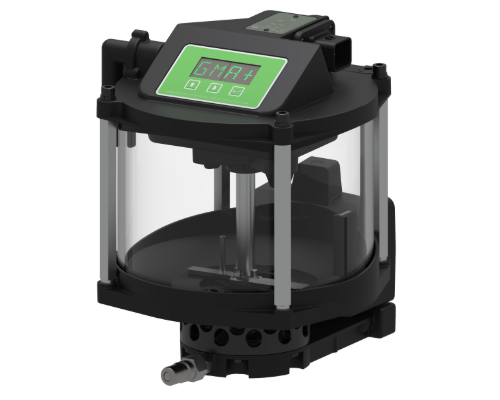

Groeneveld-BEKA's automatic lubrication systems offer a future-proof solution for harbour operators

Our systems are compatible with both conventional diesel engines and electric drives and ensure seamless integration into your evolving fleet, be it reach stackers, straddle carriers or electric terminal tractors.

With automatic lubrication, technicians no longer need to access potentially hazardous areas around moving parts or high-voltage components, contributing to a safer working environment.

Precise, pre-programmed lubrication schedules minimise wear and tear, preventing breakdowns and costly repairs that can disrupt port operations.

By automating routine maintenance tasks, technicians gain valuable time and can concentrate on more complex repairs or inspections.

Consistent lubrication promotes optimum performance and extends the life of your valuable container handling equipment, minimising replacement costs.

Minimise lubricant waste and possible contamination through precise application, benefiting both your business and the environment.

Find the right product for you!

Groeneveld-BEKA's automatic lubrication systems offer a high-performance solution