Mining

Conquering the depths: Optimised lubrication for top performance in mining

In the mining industry, the resources that power our world are extracted from deep underground. However, the smooth operation of the heavy machinery used in these demanding environments places special demands on lubrication.

Firstly, exposure to dust, dirt and moisture accelerates the wear of key components. Secondly, travelling to dangerous and potentially remote locations can make consistent manual lubrication a safety hazard and a logistical hurdle.

General advantages of our products

Our robust systems have been specially developed for the harsh conditions in mining. They can withstand dust, dirt, moisture and extreme temperatures and deliver reliable performance above and below ground.

Automatic lubrication ensures precise lubricant application at pre-programmed intervals, minimising wear and preventing equipment breakdowns that can interrupt production and disrupt tight schedules.

Automatic systems eliminate the need for staff to enter hazardous areas or climb on equipment to lubricate, minimising the risk of slips, falls and injuries.

By minimising downtime for lubrication and avoiding breakdowns, automated systems keep your mining operation running smoothly and maximise resource recovery.

Consistent lubrication promotes optimum performance and extends the service life of your valuable mining equipment, reducing spare parts costs.

Precise application minimises lubricant waste and potential environmental pollution in the mine, contributing to more sustainable operations.

Find the right product for you!

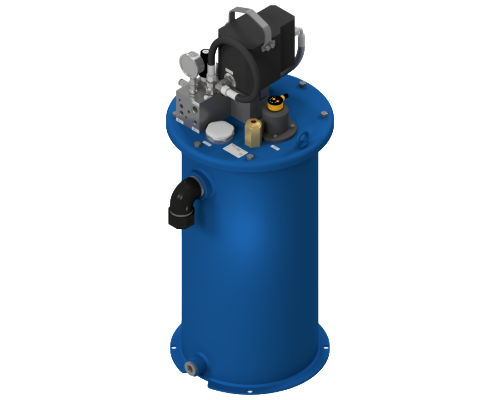

Groeneveld-BEKA's automatic lubrication systems offer a high-performance solution for mining operations