Metal industry

Efficiency in forging: optimise metal production with automatic lubrication

The metals industry relies on high-performance machinery to transform raw materials into the building blocks of our world. However, maintaining peak performance in these demanding environments is a major challenge for lubrication.

Firstly, extreme heat, pressure and metal dust accelerate the wear of critical components. Secondly, ensuring consistent lubrication in sprawling facilities with complex machinery can be a logistical nightmare for maintenance teams.

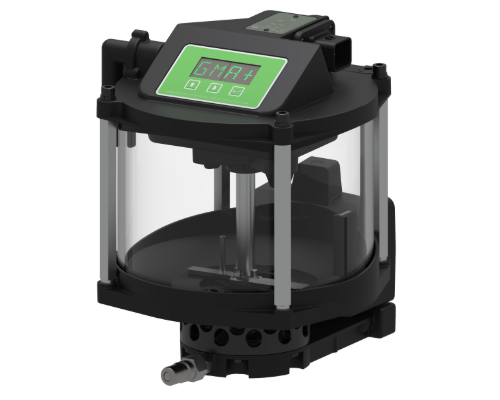

Automatic lubrication systems from Groeneveld-BEKA offer a high-performance solution for the metal industry

Our robust systems are designed for the harsh environmental conditions in metal production plants and can withstand heat, dust and heavy loads to ensure reliable lubrication.

Automatic lubrication ensures precise grease application at pre-programmed intervals, minimising wear and preventing equipment breakdowns that can interrupt production lines and lead to costly delays.

Automated systems eliminate the need for personnel to access hazardous areas around moving equipment or molten metal for lubrication, contributing to a safer working environment.

By minimising downtime for manual lubrication and preventing breakdowns, automatic systems keep your production lines running smoothly and maximise metal production.

Consistent lubrication promotes optimum performance and extends the life of your valuable metalworking machinery, reducing replacement costs.

Precise application minimises lubricant waste and possible contamination, which contributes to a clean and sustainable metal production process.

Find the right product for you!

Groeneveld-BEKA's automatic lubrication systems offer a high-performance solution for the metal industry