Internal transport

So that your bearing runs on autopilot: optimise internal transport with automatic lubrication

The efficiency of your warehouse depends on the smooth operation of your internal transport fleet, which includes pallet trucks, forklifts and other vehicles. However, maintaining these workhorses can be a challenge.

Firstly, it can be difficult to ensure consistent lubrication during busy periods, leading to increased wear and tear. Secondly, manual lubrication takes up valuable time that could be better spent on core warehouse activities.

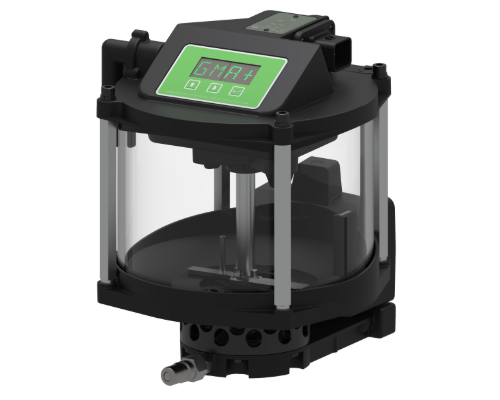

Groeneveld-BEKA's automatic lubrication systems offer a high-performance solution for in-house transport

Automatic lubrication supplies grease at precise intervals, minimises wear on critical components and prevents failures that can disrupt warehouse operations.

By automating routine lubrication tasks, you gain valuable time for your employees. Your team can concentrate on loading and unloading and ensure that your warehouse operations run smoothly.

Consistent lubrication extends the service life of your internal transport vehicles, which leads to considerable cost savings in the long term.

Automatic systems eliminate the need for operators to enter potentially hazardous areas under or around the machine to lubricate, contributing to a safer working environment.

Automatic lubrication minimises the risk of grease spillage on the bearing bases, reduces the risk of slipping and promotes a clean working area.

Precise application minimises lubricant waste and possible environmental contamination in your bearing.

Find the right product for you!

Groeneveld-BEKA's automatic lubrication systems offer a high-performance solution for your internal transport fleet