Food and beverage industry

For a smooth process in the food and beverage industry: Automated lubrication for improved production

The food and beverage industry relies on careful maintenance of its equipment to ensure hygiene, safety and optimal production. However, manual lubrication in this sector poses a number of challenges.

Maintaining strict hygiene standards requires frequent cleaning operations that can wash away manually applied grease. Secondly, ensuring consistent lubrication across complex production lines can be time consuming with a busy workforce. Finally, safety concerns regarding food contact and the potential slip hazard of grease must be carefully considered.

Automatic lubrication systems from Groeneveld-BEKA are a recipe for success in the food and beverage industry

Our systems are capable of using NSF-registered lubricants specifically formulated for incidental food contact, ensuring the safety and integrity of your products.

Automatic lubrication minimises the risk of contamination of the lubricant during the washing process and promotes a clean and hygienic production environment.

Automatic systems deliver precise quantities of lubricant at pre-programmed intervals, giving staff valuable time for other important tasks.

Automatic lubrication means that staff no longer need to access the machines to lubricate them, reducing the risk of slips and falls in production areas.

Uniform lubrication minimises wear, prevents breakdowns and extends the service life of the devices, which leads to considerable cost savings in the long term.

By minimising downtime for manual lubrication, automatic systems keep your production lines running smoothly and maximise performance.

Find the right product for you!

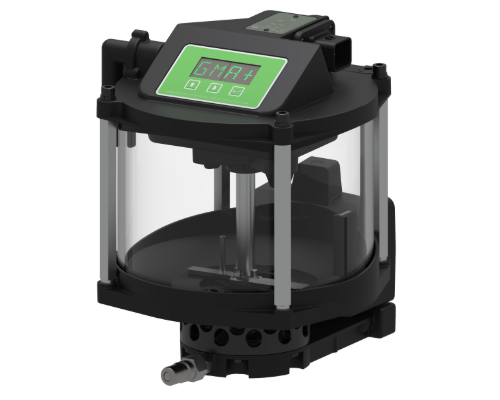

Groeneveld-BEKA's automatic lubrication systems offer a high-performance solution for the food and beverage industry