Sustainability

Ecological production

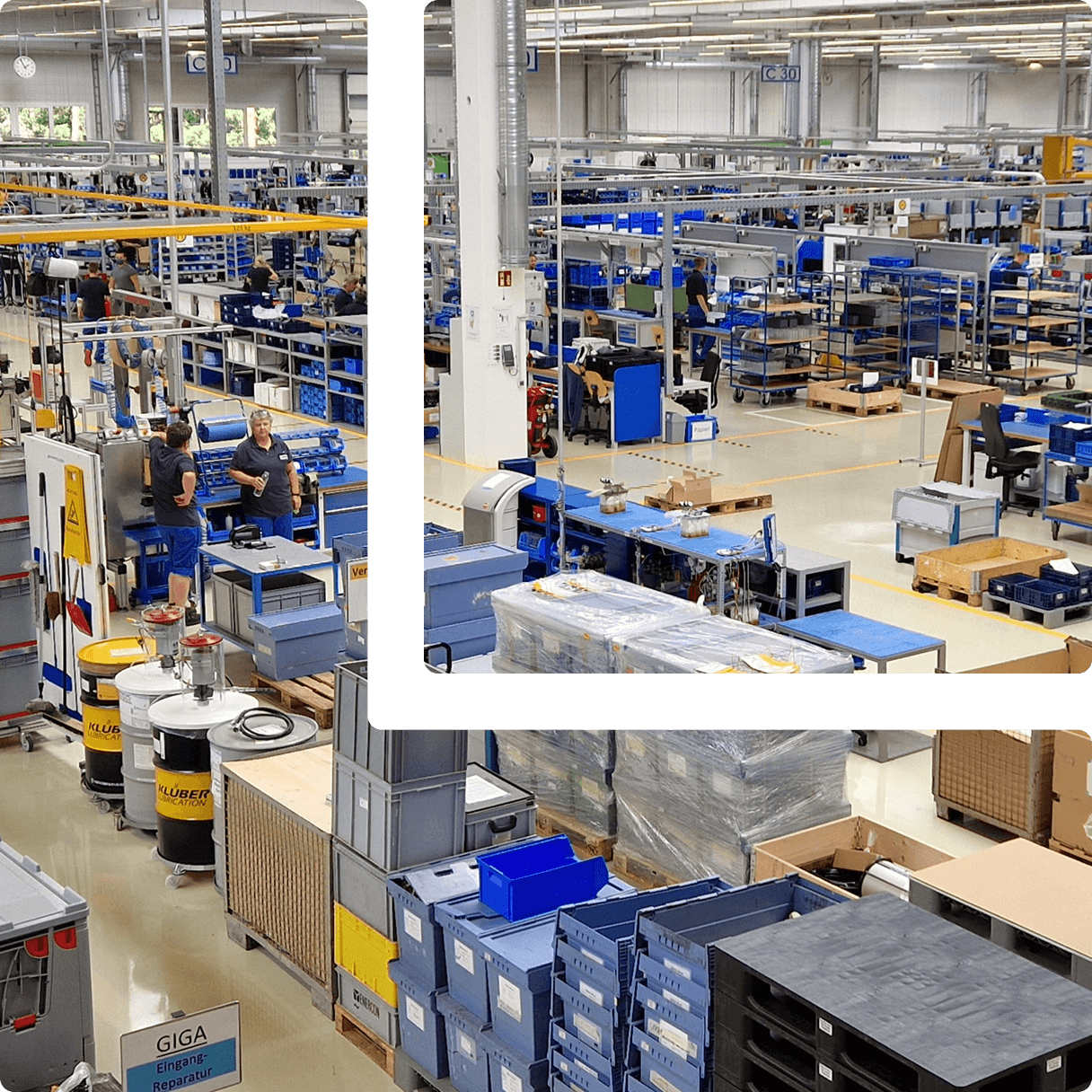

Our latest production facility in Wannberg, Germany, is a leader in reducing carbon emissions and establishing greater energy independence. When the plant first opened in 2019 it utilized 92% renewable energy through its local energy partner. Soon, the facility’s management team learned they could achieve 100% renewable energy by investing in a sustainability program with the supplier.

Nowadays the plant is 100% powered by renewable energy sources, from wind, solar, hydro and bioenergy sources. Our bigger goal is to reduce our overall energy consumption.

Environmentally friendly products

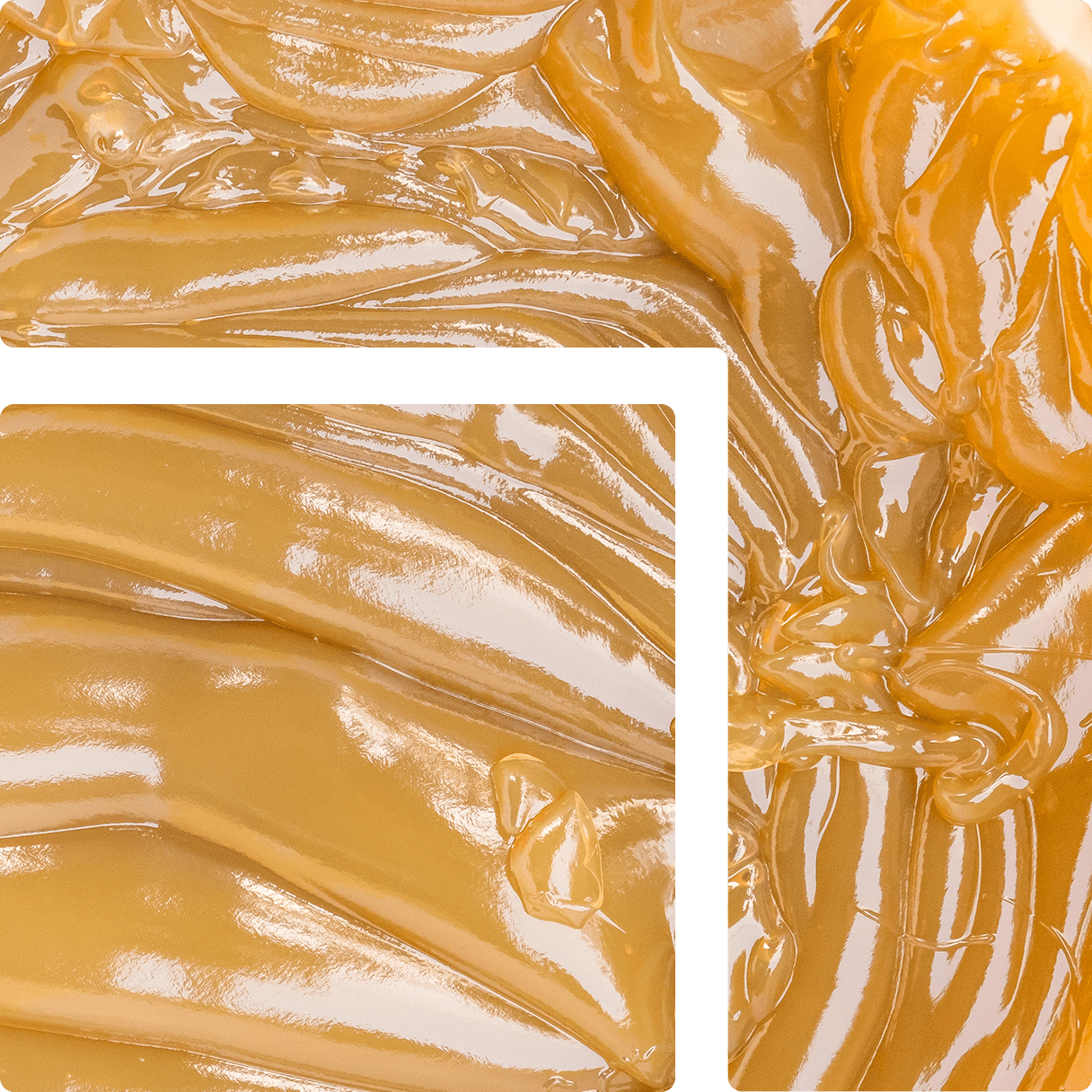

Groeneveld-BEKA is also contributing to the global drive for sustainability with our product range. The latest product update is related to the lubricating greases, where we switch from lithium-thickened grease to lithium free grease.

The carbon footprint of lithium hydroxide is 8,6 kg CO2 per kg of grease, while with calcium hydroxide it is reduced to 0.752 kg CO2 per kg. The required heating energy to produce thickeners for the lithium free greases are an impressive factor 2 lower compared to Lithium thickeners.