Mining Processing

Taming the Titans: Automatic lubrication for industrial mining

In industrial mining, huge machines such as conveyor belts and bucket wheel excavators are used to transport large quantities of material. However, the maintenance of these giants poses particular challenges for lubrication.

Firstly, the sheer size and complexity of these machines makes it difficult to ensure consistent and thorough manual lubrication of all critical points. Secondly, harsh environments with dust, debris and extreme temperatures accelerate the wear of key components.

General advantages of our products

Our scalable systems are specifically designed for huge industrial mining equipment, providing precise lubrication at every point of massive conveyor belts, bucket wheel excavators and other large machines.

Automatic lubrication ensures precise lubricant application at pre-programmed intervals, minimizing wear on critical components and preventing breakdowns that can disrupt the operation of large mines.

Automated systems eliminate the need for personnel to enter hazardous areas around moving equipment or climb towering structures such as bucket wheels to lubricate them, significantly reducing safety risks.

By minimizing downtime and streamlining maintenance, automatic lubrication enables smooth and efficient operation in industrial mining and maximizes material recovery.

Consistent lubrication promotes optimum performance and extends the life of your giant mining machines, reducing the need for costly spare parts and repairs.

Precise application minimizes lubricant waste and potential contamination in industrial mining, contributing to cleaner and more sustainable operations.

Find the right product for you!

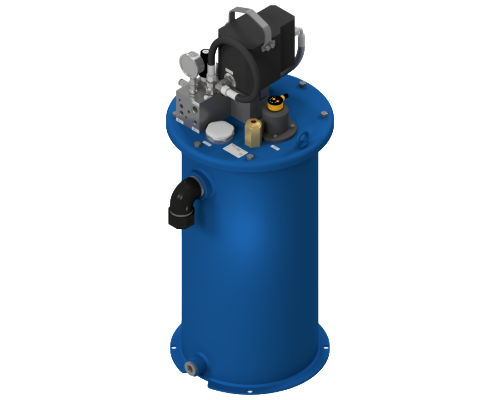

Groeneveld-BEKA's automatic lubrication systems offer a powerful solution for mining processing