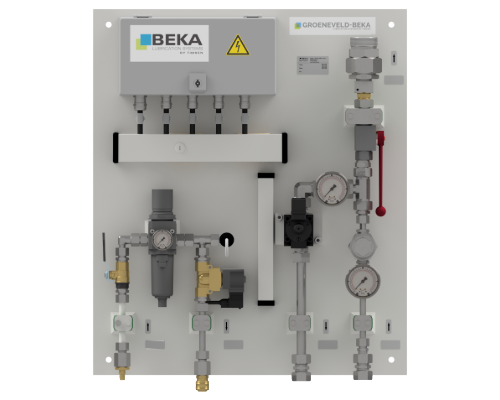

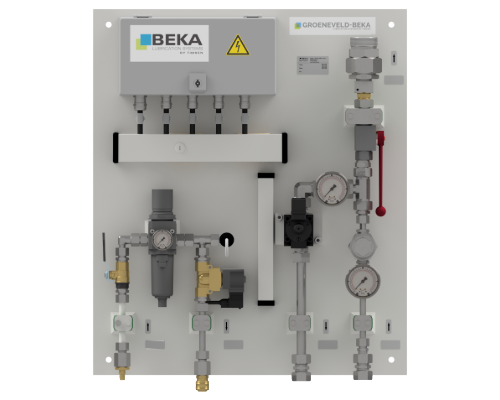

BEKA grease pump station

General

Due to the individual adaptation of the system, a grease pump station can be used as a small oil lubrication system for one or two smaller machines or also for larger machines or systems.

A grease pump station, regardless of whether it is used as a dual-line or progressive system, consists of a few standard components: a gear pump unit, a control unit, an oil sump unit, one or more monitoring devices and several metering devices.

Grease pump station as a two-line system

When used in a dual-line system, the grease is pumped to the distribution blocks via a double main line network. The metering devices supply each lubrication point with exactly the right amount of grease.

The advantage of the dual line system is that the system can cover very long distances.

Grease pumping station in the form of a progressive sectional system

In a progressive system, the lubrication system is divided into several sections. Several distributors are collected in each section. Each section is connected separately to a main line and can be lubricated individually.

Each section is operated by the control unit. The main distributors are supplied with grease via a gear pump that pumps the oil from a separate oil reservoir.

A progressive section system is most commonly used when different machines are connected to each other but do not always work at the same time. The advantage of the sectional system is that each section can be controlled independently.

Do you need more information? Do not hesitate to reach out to us

| Technical data | |

|---|---|

| Functional principle | Pneumatic drum pump |

| Lubricant | Lubricating grease up to NLGI-2 |

| Delivery volume | Approx. 0.8 l/min |

| Operating pressure | Max. 400 bar (5801 psi) |

| Operating temperature | 30 up to +80 °C / (-22 up to 176 °F) |

Download

Do you need detailed information, technical specifications or operating instructions for your Groeneveld-BEKA product? Look no further. On our Manuals & Downloads page you will find all the information you need.