BEKA Fluilub

General

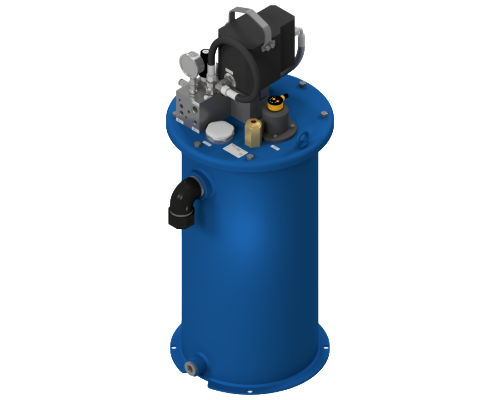

The FluiLub system is developed for using thixotropic lubricants with high solid contents, achieving an ideal combination of adhesion and flow-ability in a spray lubricant for high-stress applications. The system is installed mainly on the leading vehicle axle. Due to the lubricants used, the lubricant is transferred to the following rail heads or wheel flanges.

The system works with a special mixing distributor which divides the lubricant/air mixture precisely between the connected spray nozzles. The nozzles spray the lubricant onto the wheel flange or rail during a set spray time on both sides simultaneously.

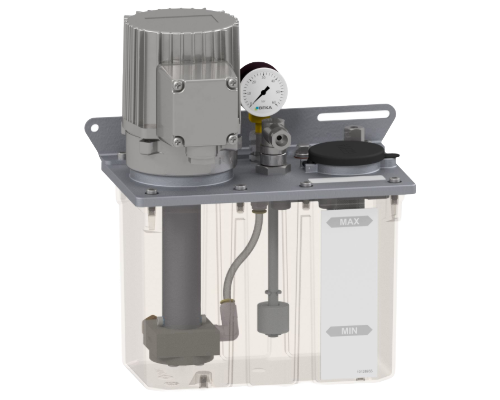

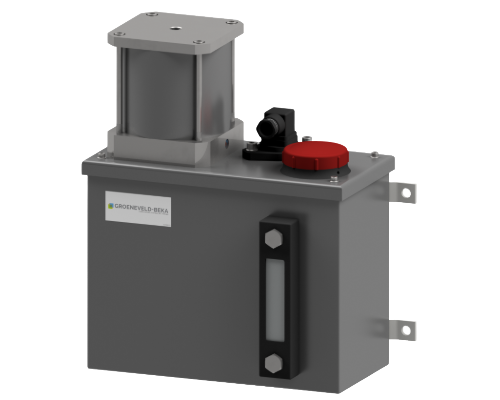

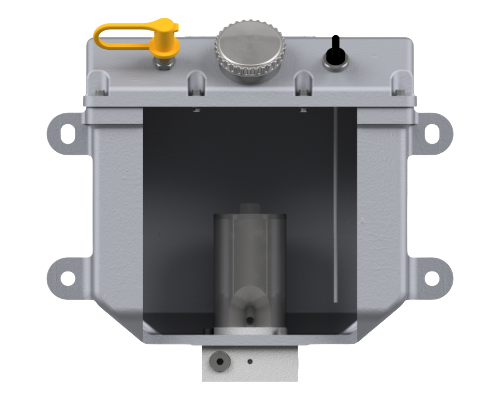

The FluiLub pump is available in two versions, the Flui I and the Flui II. The Flui II is equipped with an internal pump for a space saving installation and comes in a pre-set output rate, where the output rate of the Flui I is adjustable. As a single line pneumatic spraying system, FluiLub installations require no moving parts except for the pump. This means; less wear, little maintenance requirements and therefore low life-cycle costs.

The reservoir is available in different capacities, ranging from 5.8 up to 13 liter. Additionally, the Fluilub pumps can be ordered without a filling plug, with an external filling plug or with different couplers at the front or the side of the cover and with different delivery rates. As an option an electrical min. or max. level switch is possible.

The FluiLub system is controlled by an electronic control unit which allows you to optimally adapt the system to the operating conditions. The optional curve sensor allows the curve-dependent activation of the system.

Would you like to find out more about our solutions? We will be happy to advise you!

| Technical Data | |

|---|---|

| Function principle | Pneumatic pump |

| Outlets | 1 |

| Delivery volume Flui I | 0,1 to 1 cm3/stroke |

| Delivery volume Flui II | 0,1, 0,2 or 0,4 cm3/stroke |

| Lubricant | Oil |

| Operation temperature | -30 up to +70 °C |

| Reservoir sizes | 5.8, 8, 10 and 13 l. Custom sizes available on request |

| Material | Aluminum. Steel version upon request |

| Protection class | IP 67 |

Downloads

Do you need detailed information, technical specifications or operating instructions for your Groeneveld-BEKA product? Look no further. On our Manuals & Downloads page, you will find all the information needed.